SeccoMix R

SeccoMix R

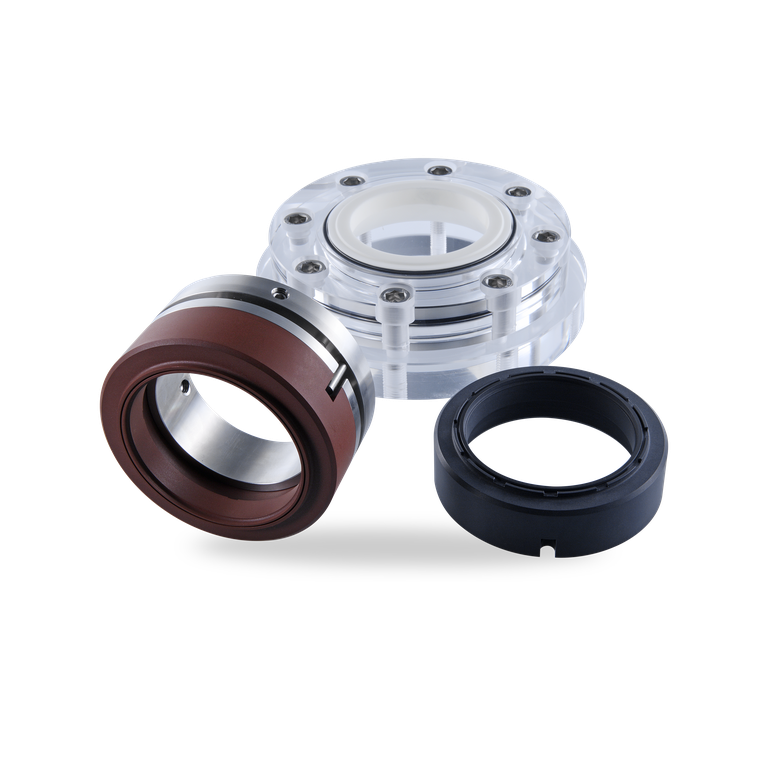

| Item | Description |

| 1 | Seal face, product side |

| 2 | Seat, product side |

| 3 | O-Ring, dynamic |

| 4 | Seat, atmosphere side |

| 5 | O-Ring |

| 6 | Seal face, atmosphere side |

SeccoMix R

Features

- For top, side and bottom entry drives

- Dry running

- Nitrogen pressurized dual seal

- Rotating seat at product side

- Balanced

- Independent of direction of rotation

Advantages

- Ready-to-fit and factory-tested units

- With or without bearing available

- Smooth surface, free of dead spaces

- No contamination of the product by barrier fluid

- Friction-locked connection to the shaft

- ATEX certification available on request

Materials

Seal face: Carbon graphite, FDA conform

Seat: Silicon carbide, FDA conform

Secondary seals and metal parts according to application and customer's specifications.

Seat: Silicon carbide, FDA conform

Secondary seals and metal parts according to application and customer's specifications.

Standards and approvals

- FDA

- ATEX

- Compliant to TA Luft (German Clean Air Act)

Recommended applications

- Refining technology

- Petrochemical industry

- Chemical industry

- Pharmaceutical industry

- Food and beverage industry

- Agitators

- Mixers

- Kneaders

- Dryers

- Reactors

Notes

Options:

- Axial bellows expansion joint (shaft movement)

- Scraper (shaft movement)

Recommended piping plans

Gas supply

EagleBurgmann GSS4015/A400-D0

for double seals SeccoMix R

EagleBurgmann GSS4015/A400-D0

for double seals SeccoMix R

Product variants

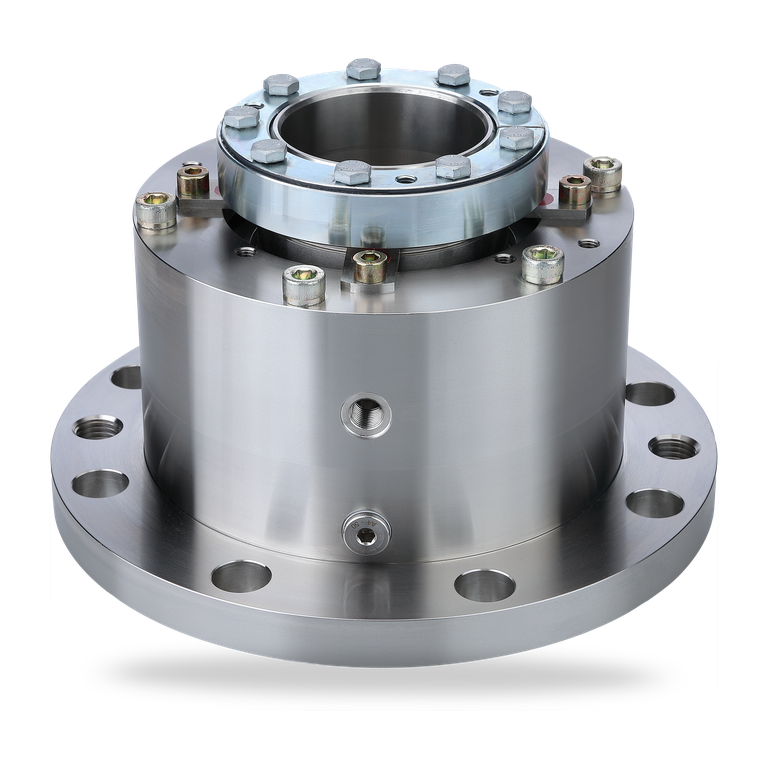

SeccoMix R3

Dual seal with solid seat and integrated floating bearing d1 ≤140 mm (5,51").

As an option with fixed bearing or without bearing available.

Dual seal with solid seat and integrated floating bearing d1 ≤140 mm (5,51").

As an option with fixed bearing or without bearing available.

SeccoMix R5

Dual seal with „hook-sleeve“ and integrated floating bearing d1 >140 mm (5,51").

As an option with fixed bearing or without bearing available.

Dual seal with „hook-sleeve“ and integrated floating bearing d1 >140 mm (5,51").

As an option with fixed bearing or without bearing available.

Similar products

AD510 / AD520

- Dry running

- Single seal

- Independent of direction of rotation

SeccoLip461

- For top entry drives, on request for side and bottom entry drives

- For glass-lined vessels

- Dry-running

- Modular and flexible design

- Compensation of shaft deflection by patented technology

- Independent of direction of rotation

- Cartridge unit

SeccoLip481

- For top entry drive;

side drive also available on request - For stainless steel vessels

- Dry-running

- Modular and flexible design

- Compensation of shaft deflection by patented technology

- Independent of direction of rotation

- Cartridge unit

- Variant available for applications with product contact (SeccoLipR)