EagleBurgmann International

EagleBurgmann WELTWEIT

Mit rund 250 Standorten und 90 Servicecentern, sind wir in den bedeutenden Wirtschaftsregionen vertreten. Die Vorteile liegen klar auf der Hand: kurze Wege zu unseren Kunden, schnelle Reaktionszeiten und die gleiche Sprache.

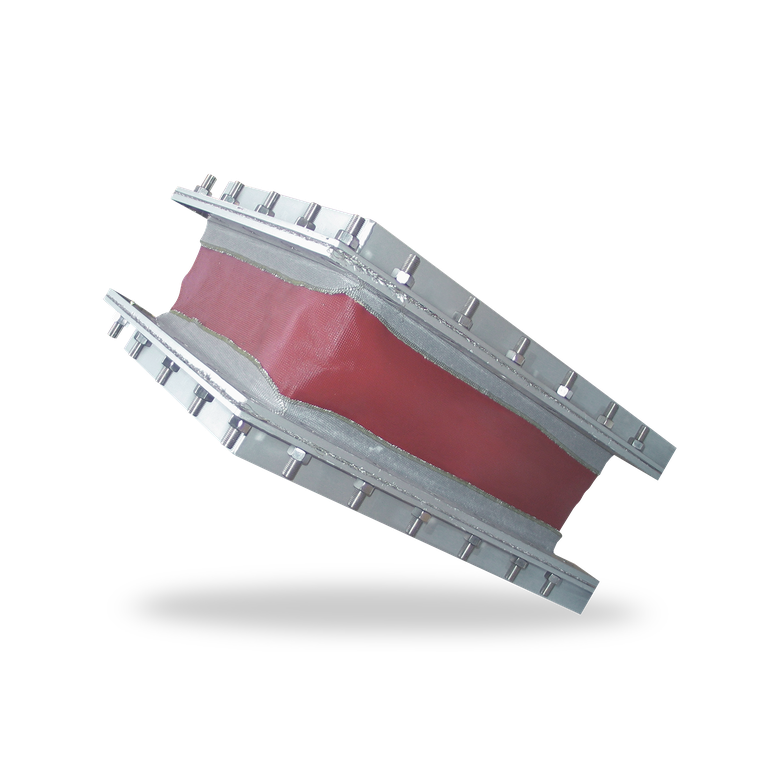

Acouseal

expansion joint

| Item | Description |

| 1, 4 | Duct flange |

| 2 | Clamp bar |

| 3 | Expansion joint |

Acouseal

expansion joint

Merkmale

- Single layer design

- Designed for acoustic demanding environment in GT inlets

- Absorbs movements and vibrations in multiple directions

- 100 % gas tight connection

- Excellent and proven sound reducing properties

Vorteile

- Delivered pre-shaped at required dimensions

- Can upon request be delivered with pre punched holes for easy installation

- Proven sound reduction abilities

- Improved acoustic environment around GT inlet system

- Easy transportation and storage

- Self-sealing expansion joint (no gasket needed during installation)

Einsatzbereich

-35 °C … +150 °C (-31 °F ... +302 °F)

Pressure:

-0.1 bar … 0.1 bar (-1.45 PSI ... 1.45 PSI)

Maximal axial movement: ... 30 mm (1”)

Maximal lateral movement: ... 15 mm (1/2”)

Standards und Freigaben

- EN 10204-2.2 Certificate

- Safety Data Sheet (SDS) for base material

Empfohlene Anwendungen

- Oil and gas industry

- Power plant technology

- Gas turbine inlets

- Boiler outlets

Funktionsbeschreibung

Ähnliche Produkte

Combine-X expansion joints

- Multi layer design

- Compensates for movements in several directions simultaneously

- Excellent form stability

- Can be delivered as fabric only or as preassembled unit

- Custom made to fit actual working conditions

- Specifically designed for gas turbine systems

Flexgen expansion joints

- Multi layer design (Flexgen 2002: single layer construction)

- Compensates for movements in several directions simultaneously

- Can be delivered as fabric only or as preassembled unit

- For dry condition

- Custom made to fit actual working conditions

Fluachem expansion joints

- Single layer design

- Compensates for movements in several directions simultaneously

- Can be delivered as fabric only or as preassembled drop in unit

- For dry and wet condition

- Custom made to fit actual working conditions

Individuelle Lösung anfragen

Wir entwickeln und produzieren kundenspezifische Sonder- und Einzellösungen für jeden Anwendungsfall.

Unternehmensgruppe

Dichtungstechnologie für Maschinen und Anlagen

EagleBurgmann ist einer der weltweit führenden Anbieter von industrieller Dichtungstechnologie. Unsere mechanischen Dichtungen, Dichtungsversorgungssysteme, Magnetkupplungen, Kohleschwimmringdichtungen, Kompensatoren, Flachdichtungen und Packungen sowie unser umfassender Service kommen überall zum Einsatz, wo es um Zuverlässigkeit und Sicherheit geht.

Mechanische Dichtungen und mehr

Die Dichtungstechnologie von EagleBurgmann wird weltweit unter anderem in der Öl- und Gasindustrie, in Raffinerien, petrochemischen, chemischen und pharmazeutischen Betrieben, in der Lebensmittelverarbeitung, in der Energie- und Wasserwirtschaft, im Bergbau, bei der Papierherstellung und in der Raumfahrt verwendet. Fast 5.800 Mitarbeiter bringen ihre Ideen und Lösungen und ihr Engagement ein, damit sich unsere Kunden auf unsere Dichtungstechnologie verlassen können.

Was uns einzigartig macht, sind unsere hervorragende Qualität, unsere große Innovationskraft und ein umfassendes Produktangebot für nahezu alle industriellen Prozesse und Anwendungsgebiete. Unser Produktportfolio umfasst alles von mechanischen Dichtungen und Dichtungsversorgungssystemen über Magnetkupplungen, Kohleschwimmringdichtungen, Kompensatoren, Flachdichtungen und Packungen bis hin zu unserem umfangreichen Service. Da wir ein Teil der deutschen Freudenberg- und der japanischen EKK-Gruppe sind, verfügen wir über alle notwendigen Ressourcen für eine verlässliche Partnerschaft mit starkem Fundament.